Vision Miner 22 IDEX V4

$POA

350 x 350 x 450mm

500°C Hotends with Independent Dual Extruders (IDEX)

Print Modes: MIRROR, DUPLICATE, or MULTI-MATERIAL

5-Axis Build Platform Mechanical Self-Leveling

Actively Heated Chamber for High Temperature Polymers

Engineered for industrial performance with over 200 upgrades on v3

Engineered for Industrial Performance

The 22 IDEX v4 is a high-temperature industrial 3D printer built for real production. Designed and refined through four generations, this machine is engineered for professionals who print true engineering-grade materials like PEEK, ULTEM, PPSU, CF-Nylon, and Polycarbonate without paying $100K+ price tag for a proprietary system. If you’re searching for a high-temperature dual-extrusion 3D printer that delivers industrial reliability, precision, and throughput, this is it.

From the start, Vision Miner’s goal wasn’t to build the printer of our dreams, it was to build the printer you actually need. The 22 IDEX v4 is designed for real-world manufacturing, research labs, defense contractors, and engineering teams that demand consistency and control. Every inch of this fourth-generation machine is refined for performance, serviceability, and uptime. With over 200 updates since the V3, it’s tougher, smarter, and easier to maintain. Built from welded steel and insulated with stainless steel and foam, the v4 creates a true thermal ecosystem.

Heated Chamber and 2x 500°C Nozzles

The heated chamber reaches 100°C, the bed 200°C, and each nozzle hits 500°C, unlocking virtually any thermoplastic filament on the market. That means stronger parts, better interlayer adhesion, and reliable precision with materials like ABS, Nylon, Polycarbonate, PEEK, and ULTEM. Internal reflection surfaces and thermal optimization reduce energy use while improving part quality, especially for high-warp polymers.

IDEX and Print Modes

The machine’s dual independent extrusion (IDEX) system allows you to print with two materials, support structures, or mirror/duplicate parts for double throughput. You can pair carbon-fiber-reinforced materials with unfilled nylons, soluble supports, or multiple nozzle sizes, all while maintaining accuracy. Features like input shaping, automatic calibration of X/Y/Z offsets, and mechanical bed leveling eliminate the pain of dual-nozzle setups. No shims, no paper tricks — just one-button precision. Industrial environments demand more than print quality — they need reliability and control.

Excellent Safety Features

The 22 IDEX v4 includes filtration with HEPA and carbon recirculation, optional external fume extraction, Wi-Fi and Ethernet connectivity, touchscreen convenience, and full web-based management. Print, monitor, and adjust jobs remotely while maintaining chamber integrity. Lockable doors and lids add safety and security for labs, schools, and classified spaces. With bench and vehicle mounting points, the v4 can run in field environments or mobile print farms. It’s ruggedized for deployment and built to move. Whether bolted into a research vehicle, a defense lab, or a factory bench, it’s designed to survive and perform anywhere.

Reliability and Support

The 22 IDEX v4 bridges the gap between $100K industrial systems and consumer-grade hobby machines. It provides true high-temperature capability, industrial reliability, and scalability. Customers include the U.S. Department of Defense, Lockheed Martin, Northrop Grumman, the Hadron Collider, Caltech, Stanford, and research institutions worldwide. They choose Vision Miner because they can’t afford excuses — and because the machines simply perform. Vision Miner back every printer with real human support. Their U.S.-based team provides direct phone and email assistance, detailed online documentation, and serviceability by design. The v4 uses accessible, off-the-shelf components to minimize downtime and maximize independence. No proprietary locks, no forced material systems — just capability.

Vision Miner specialise in functional 3D printing, especially high-performance plastics like PEEK, ULTEM, PPSU, PPS, CFPA, and more. They also have extensive experience with 3D scanners, and a whole array of solutions available for purchase. If you're interested in using functional 3D printing and materials in your business, feel free to reach out to the 3Design team, and we can help you make the right choice for your application.

-

Build Size: 350 × 350 × 450mm

Extruder Type: LGX Pro High-Temp Dual-Gear Extruders.

Chamber Heating: 100°C

Filament Conditioning: Integrated Heated Chamber Storage

Print Speed (max): 500mm/s, 30-300mm/s (recommended)

Multiple Print Modes:

Mirror Mode (2×175)×350×450mm

Duplication Mode (2×175)×350×450mm

Extruder Quantity: 2

Nozzle Diameter: Hardened Steel 0.4mm standard (0.6, 0.8, 1.0mm optional)

Extruder Temperature: ≤500°C

Platform Temperature: ≤200°C, 5-axis build platform mechanical self-leveling

Print Precision: ± 0.1 mm

Fume Extraction Options: 2” inlet/outlet for external system OR HEPA + Active Carbon Filter System

Connectivity: Duet Web Control Interface, Modular WiFi Module, Integrated Ethernet, USB

Supported Software: PrusaSlicer, Simplify3D, Orca Slicer, +more

Operating Systems: Windows, macOS, Linux, Android, iOS, Accessed via Standard Web Browser

-

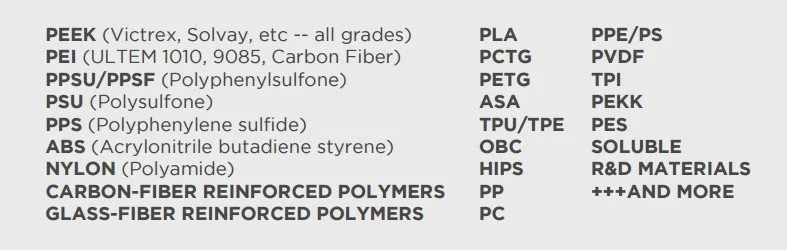

Supports any 1.75mm filament: PEEK, PEKK, CFPEEK, AM200 PAEK, PEI, ULTEM™ 9085, ULTEM™ 1010, PPSU, PA/CF, Nylon (PA66, PA6, PA12), PC, PC Alloys, ABS, ASA, PETG, HIPS, PLA, PVA, TPU, ESD, Metal-Filled, Glass-Filled, Soluble Supports, and more.

100% Open Material System

-

Input Power: 110/240V - 50/60Hz

Rated Power: 2200W max, dedicated 15A

Resume Printing: Save data when power off

Filament Detection: Pause when filament runs out

-

Machine Dimensions: 535 x 568 x 739 mm

Machine Weight: 90.7 Kg

Package Weight: 100 Kg

Crate Size: 69 × 66 × 94 cm

22 IDEX v4 Full Overview and Technical Deep Dive

Material Compatibility

Multiple Print Modes

Vision Miner 22 IDEX v3 Mirror and Duplicate Print Modes